Energy management: WH-EnMS

The intelligent Wehrhahn energy saving management system

Today a number of business facilities are facing the challenge of reducing costs by energy saving methods and to even optimize production and working process.

If you run a production line or carry out a trade and you want to...

- produce in an energy-saving way

- reduce the running and long-term cost

- optimise quality of your products

- ensure enduring and environmentally sustainable production

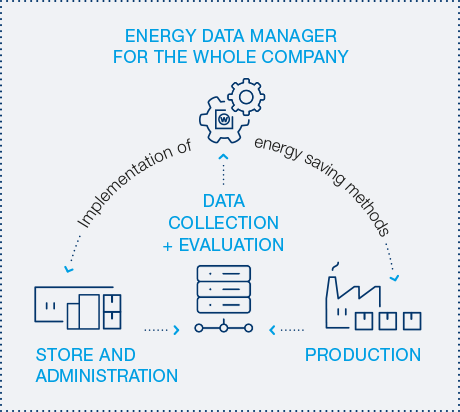

The Wehrhahn energy management system WH-EnMS enables you to meet and certify energy standards according to ISO 50001.

Know-how, special software, incl. project planning und installation of a measuring system, energy data analysis, application of energy saving methods and installation of energy saving components – if required as complete or partial solution.

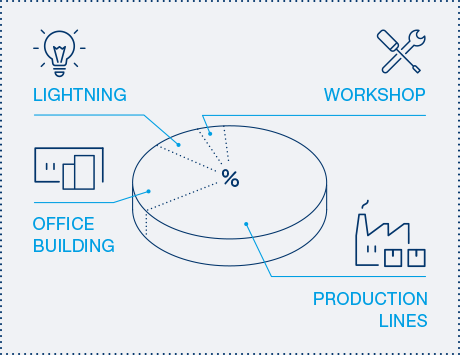

The WH-EnMS considers the whole energy requirement of your company, including electric power and gas consumption in consideration of key performance indicators (KPIs) as well as energy performance indicators (EnPIs) from all production lines, storage rooms, office buildings, etc.

Please contact us!

Highly skilled Wehrhahn experts spend their know-how, qualification and experience to realize energy saving methods in your company for utmost efficiency.

As an experienced solution provider for energy management systems in various production plants SIEMENS is recommending Wehrhahn as competent “EM partner”. The Wehrhahn energy management system WH-EnMS is operating with SIEMENS SENTRON components. Wehrhahn has long-term experience as plant supplier for the building material industry. Consequently energy saving methods for your company cannot only be identified, but also directly implemented by the Wehrhahn team.

Intelligent energy saving – made by Wehrhahn.