Wehrhahn technical service / consulting

As a global market leader in the design and manufacture of highly efficient building material production plants, Wehrhahn meets the highest standards of reliability, quality and cost-effectiveness.

Our headquarters in Delmenhorst are home not only to our machine design, plant development and administration sectors, but also to our engineering works with the latest machine tools.

After manufacture, every Wehrhahn machine undergoes function testing before the plant – pre-assembled as far as possible – is shipped to the client.

Installation and servicing

Installation, commissioning and start-up of the plants at their final destination is overseen by our highly qualified engineers and programmers. The scope of support provided depends on the requirements in each case and ranges from a few service inspections to complete installation.

Even after commissioning and start-up we are always on hand to help, either personally or by remote maintenance on request.

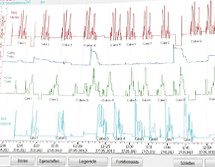

Wehrhahn remote maintenance

After production commences, the plant can be monitored via internet. Personal on-site support by our specialists is of course also available at any time.

The main advantages of Wehrhahn remote maintenance are:

- simple installation of modifications

- parameter transfer possible in both directions

- Wehrhahn engineers can intervene during normal operation

- no travel costs

Wehrhahn training courses

Your staff is trained by professionals who teach the basic expertise necessary to ensure trouble-free operation of your plant.

Client-specific plant design and service

We deliver solutions for success: as well as construction projects from scratch, we also develop innovative concepts for the upgrading of existing plants.

An experienced team of engineers and technicians provides support with both mechanical and electronic aspects from initial design to successful implementation. Detailed advanced planning ensures the trouble-free and timely start-up of your plant.