Autoclaved aerated concrete production plants

Efficient, feasible and custom made.

Wehrhahn supplies complete plants or individual machines, depending entirely on specific requirements of our clients. We take account of all the relevant factors and conditions, such as production quantities, location, space available, level of investment and much more.

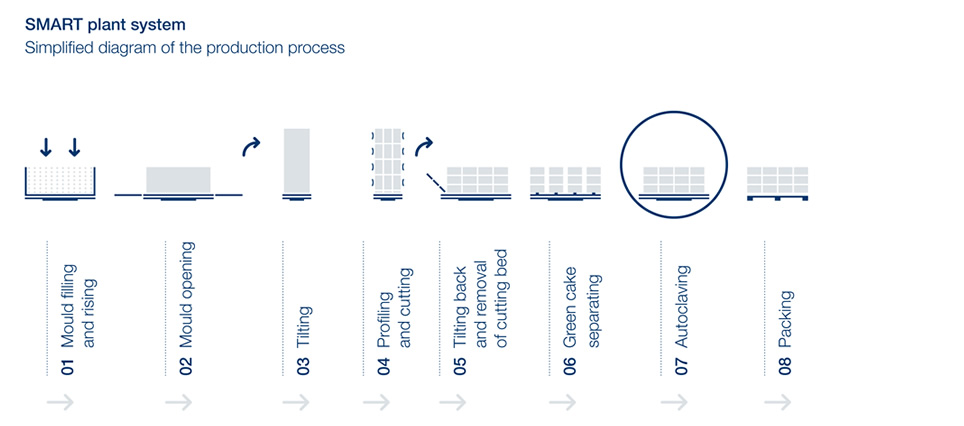

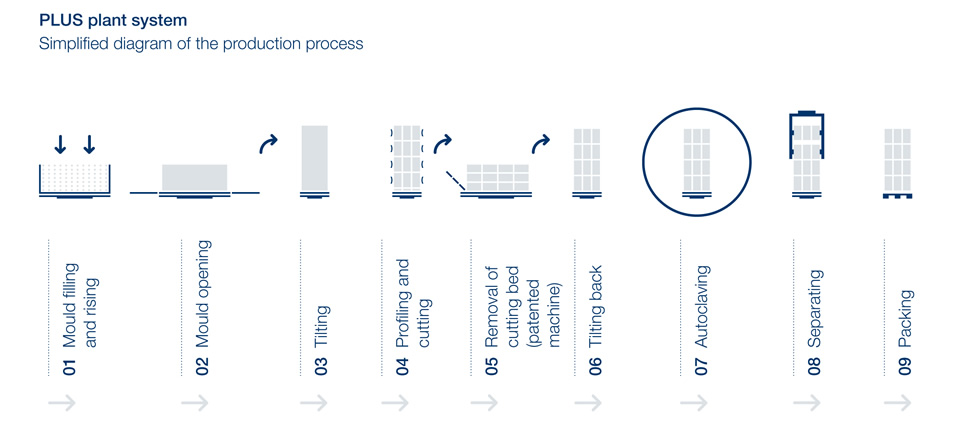

Wehrhahn’s advanced, modular and versatile plant systems allow investors to select the best suited plant from a choice of AAC plant systems all formed by repositioning and combining the proven Wehrhahn machines in different sequences and positions.

It is common in all plant types that the cake is cut in vertical position. This ensures highest possible cutting accuracy and facilitates profiling and cutting of hand holds prior to autoclaving.

Maximum system performance

We offer two plant concepts with capacities from 200 up to 2.000 m3 per day to ideally serve the individual requirements of our customers. The quality of the AAC products is equally high across the different plant concepts. Which plant is the right choice for you? We will be happy to advise you. And the plant will be tailored to your specific requirements. It is characteristic for both plant concepts that the cake is cut in an upright position. This enables maximum cutting precision and profiling of the cake before autoclaving.