Wehrhahn - Autoclaved Aerated Concrete (AAC) technology

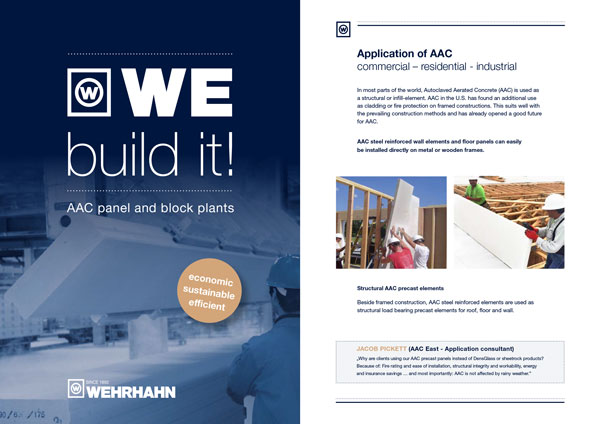

AAC is a high-quality, versatile building material which can be produced as blocks, megablocks or panels.

Wehrhahn AAC plants ensure outstanding levels of productivity and flexibility: no system waste, highest precision cutting, low energy requirements (optimum kWh/m³ values) and minimal consumption of raw materials. Far more than 100 plants for the production of high quality AAC blocks and panels are in use worldwide.

Systematic high efficiency!

AAC is a high-quality, versatile building material which can be produced as blocks, megablocks or panels.

Wehrhahn AAC plants ensure outstanding levels of productivity and flexibility: no system waste, highest precision cutting, low energy requirements (optimum kWh/m³ values) and minimal consumption of raw materials. Far more than 100 plants for the production of high quality AAC blocks and panels are in use worldwide.

Systematic high efficiency!

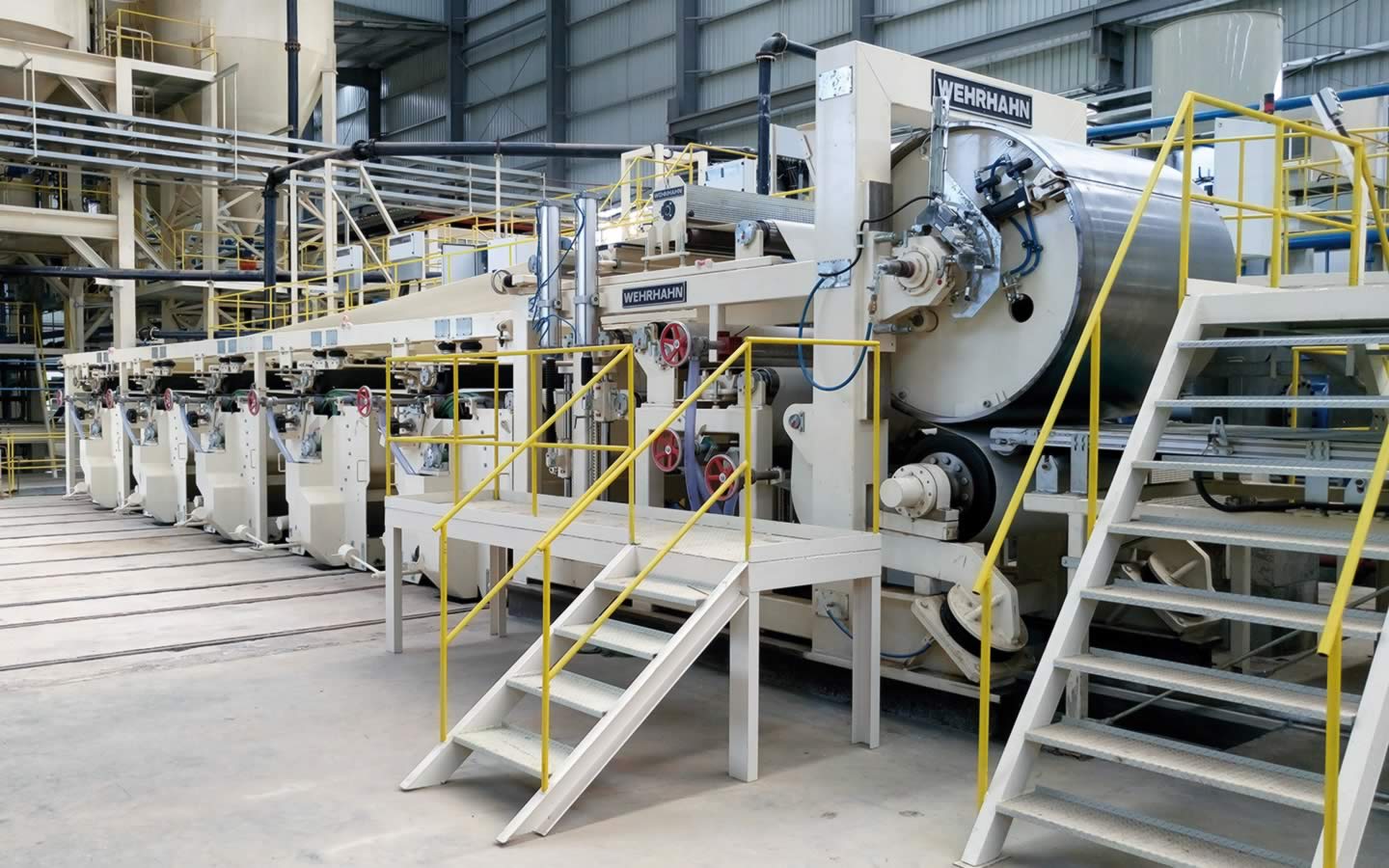

Wehrhahn – Autoclaved Flat Sheet Production

Fibre cement sheets have ideal characteristics which come into their own in particularly challenging climate conditions: heat-resistant and frost-proof, non-combustible and resistant to termite infestation.

Wehrhahn's efficient, fully automated fibre cement sheet production plants are well proven for the industrial production of aircured and steam cured (autoclaved) fibre cement sheets. Far more than 100 plants for the production of high quality fibre cement sheets are in use worldwide.

Fibre cement sheets have ideal characteristics which come into their own in particularly challenging climate conditions: heat-resistant and frost-proof, non-combustible and resistant to termite infestation.

Wehrhahn's efficient, fully automated fibre cement sheet production plants are well proven for the industrial production of aircured and steam cured (autoclaved) fibre cement sheets. Far more than 100 plants for the production of high quality fibre cement sheets are in use worldwide.

Discover creativity!

Wehrhahn Automation - the perfect run of events...

Wehrhahn Automation offers electric and automation solutions not only for Wehrhahn plants but also for all kind of production processes in a wide range of industrial branches. Every individual part of a production plant is a link in a long chain of actions and reactions.

The key is perfect flow!

Wehrhahn Automation offers electric and automation solutions not only for Wehrhahn plants but also for all kind of production processes in a wide range of industrial branches. Every individual part of a production plant is a link in a long chain of actions and reactions.

The key is perfect flow!

Wehrhahn AAC plants: zero system waste, highest-precision cutting, low energy requirements (optimum kWh/m³ values) and minimal consumption of raw materials.

AAC plants type "SMART": After upright cutting the cake is tilted back to horizontal position for green cake separating. Panels cn be produced with super-smooth surface. Capacities up to 2,000 m³ per day.

AAC plants type "SMART": After upright cutting the cake is tilted back to horizontal position for green cake separating. Panels cn be produced with super-smooth surface. Capacities up to 2,000 m³ per day.

Wehrhahn AAC plants: zero system waste, highest-precision cutting, low energy requirements (optimum kWh/m³ values) and minimal consumption of raw materials.

AAC plants type “PLUS”: The only AAC production plant on the market for upright cake autoclaving which facilitates zero process waste by using Wehrhahn's patented bed remover. Compact plant design, easy handling in the packing section. Capacities up to 1,400 m³ per day.

AAC plants type “PLUS”: The only AAC production plant on the market for upright cake autoclaving which facilitates zero process waste by using Wehrhahn's patented bed remover. Compact plant design, easy handling in the packing section. Capacities up to 1,400 m³ per day.

Wehrhahn - leading in Fibre Cement technology

Fibre cement sheets have ideal characteristics which come into their own in particularly challenging climate conditions: heat-resistant and frost-proof, non-combustible and resistant to termite infestation.

Wehrhahn's efficient, fully automated fibre cementsheet production plants are well proven for the industrial production of steam cured (autoclaved) fibre cement sheets. Far more than 100 plants for the production of high quality fibre cement sheets are in use worldwide.

Fibre cement sheets have ideal characteristics which come into their own in particularly challenging climate conditions: heat-resistant and frost-proof, non-combustible and resistant to termite infestation.

Wehrhahn's efficient, fully automated fibre cementsheet production plants are well proven for the industrial production of steam cured (autoclaved) fibre cement sheets. Far more than 100 plants for the production of high quality fibre cement sheets are in use worldwide.

Discover creativity!

Wehrhahn - leading in Fibre Cement technology

Fibre cement sheets have ideal characteristics which come into their own in particularly challenging climate conditions: heat-resistant and frost-proof, non-combustible and resistant to termite infestation.

Wehrhahn's efficient, fully automated fibre cement sheet production plants are well proven for the industrial production of aircured (corrugated) fibre cement sheets. Far more than 100 plants for the production of high quality fibre cement sheets are in use worldwide.

Fibre cement sheets have ideal characteristics which come into their own in particularly challenging climate conditions: heat-resistant and frost-proof, non-combustible and resistant to termite infestation.

Wehrhahn's efficient, fully automated fibre cement sheet production plants are well proven for the industrial production of aircured (corrugated) fibre cement sheets. Far more than 100 plants for the production of high quality fibre cement sheets are in use worldwide.

Discover creativity!

Hard burnt lime for the production of AAC, soft and medium burnt lime for other applications: Lime which complies with the required specification is often not available near a production facility.

Wehrhahn turnkey lime processing plants, optimal for the production of uniformly burnt high quality lime.

Wehrhahn turnkey lime processing plants, optimal for the production of uniformly burnt high quality lime.