Come visit us at THE BIG 5 Saudi 2022 in Riyadh!

Register and find our stand number 2E24!

After years of AAC production, changing product requirements, evolving technology standards and changes in the market can affect the competitiveness of an AAC plant. But how to respond and stay competitive? What's next?

Find out in our new article in the latest edition of the AAC Worldwide!

Check out our newly launched Company Channel on the Website of the AAC Worldwide:

https://www.aac-worldwide.com/channels/wehrhahn

Read and download articles published by Wehrhahn and explore our photo dashboard!

We happily announce that Wehrhahn customer Soceram in Romania successfully autoclaved their first cake.

Live on June 15th and 16th 2021.

The online concrete exhibition can be visited anytime via: www.iccx.org/digital

Get your visitor registration for free and visit the Wehrhahn booth.

Modern Wehrhahn AAC production plants are designed to allow utmost flexible conditions for both block and panel production.

Wehrhahn attended the 40th Annual Chinese AAC Conference held in Chongqing November 15-17 2020. Many AAC equipment manufacturers and big brand names attended and shared knowledge and news.

Baopeng from Jiangsu in China has revealed to be the largest AAC panel producer in China. Jiangsu Baopeng, a subsidiary of Baosteel, has been successfully producing AAC panels using the "sharpest knife" in the panel making industry: Wehrhahn superSMART.

Congratulations to Jiangsu Baopeng for this outstanding performance!

Bestsellers in China: high quality AAC panels produced with Wehrhahn technology

Today, Wehrhahn plants produce more efficiently than ever before.

The Remote Technical Service becomes increasingly important. Some months ago it was considered impossible that a production plant could even be installed and then put into operation without the presence of Wehrhahn specialists at site. We are now proving the opposite!

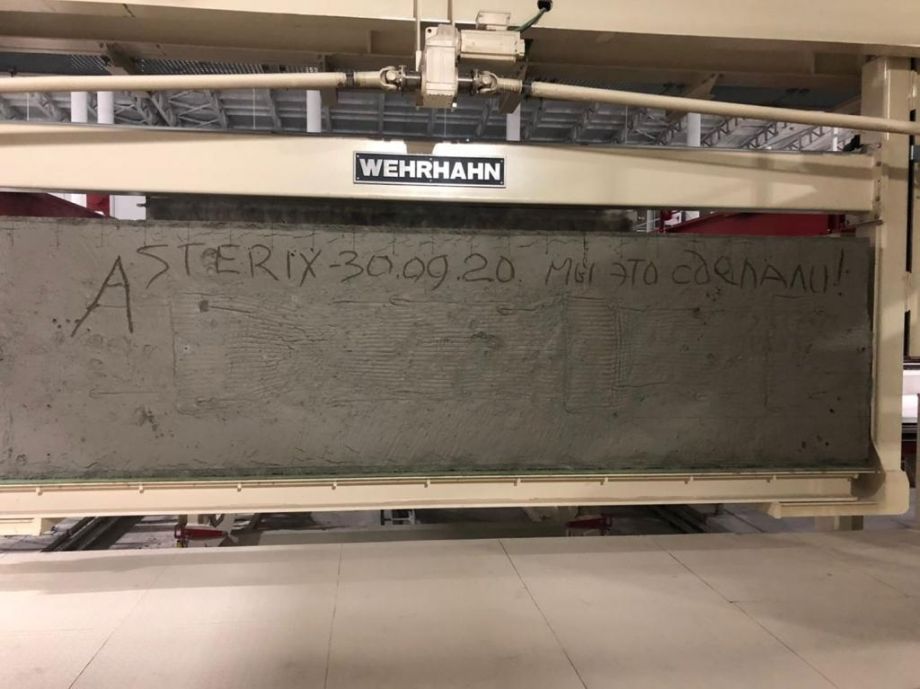

Due to the Coronavirus pandemic, the commissioning of an aerated concrete production plant for blocks and the production of the „first cake" at one of our customers in Uzbekistan were supported by Wehrhahn Remote Service. The inscription in the „first cake" (after the date) means: - мы это сделали! - We did it!

In addition to our congratulations to our customer, he expressed his thanks and appreciation to the entire Wehrhahn team, including with the statement „Working like a Swiss watch."

Some previous articles from Wehrhahn highlighted suitable components to ensure a consistent and perfect quality of AAC.

In this article, Wehrhahn introduces the WH-EnMS. The complex system measures and stores energy data from nearly each machine and section - every second!